- You have no items in your shopping cart

- Continue Shopping

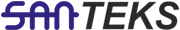

Double roller narrow weave JYF5 8/55

$1.00

Double roller narrow weave JYF5 8/55

It is a special weaving machine that is designed for mass production, weaving narrow width fabrics or regional weaving in passages and weaving tapes with various features. Factors such as the number of tapes to be woven in the double cylinder, its width, the pattern mechanism used, the number of frames, and the properties of the raw material affect the speed of the machine.

Narrow Weaving Machine Features

The rotational movement of the engine of our double roller narrow weaving JYF5 8/55 machine is distributed from the crankshaft to the hooks, combs, jacquards, dobby, drafting rollers and frames in combination by means of eccentrics, bearings and articulated arms.

The speed may vary according to the products to be touched. Its warps are prepared on specially developed flat warping machines that are unique to this type of loom.

In these machines, the warp is prepared directly with the dimensions and the warps to the weaving beam, as many passages as there are in the machine. In other words, the warp of each passage works independently in the weaving machine.

- The technology used in weaving narrow width fabrics is carried on narrow width weaving machines called needle or tape weaving machines.

- Nowadays, developments under traditional and technical textiles with various weaving technology for narrow width fabrics are increasing rapidly and potentially high demand for such products is expected.

- Entrepreneurs can leverage this technology to launch innovative products with high unique selling proposition.

The double roller narrow weave JYF5 8/55 is equipped with jacquard, pattern making and programming software to create contemporary fabrics. Narrow fabrics using materials such as polypropylene, polyester, cotton, nylon, carbon, aramid are more suitable for a wide variety of applications, such as garments, bags, shoelaces, fancy ribbons, sandals, wrist bands, seat belts, waist belts.

In Which Areas Are Narrow Weaving Machines Used?

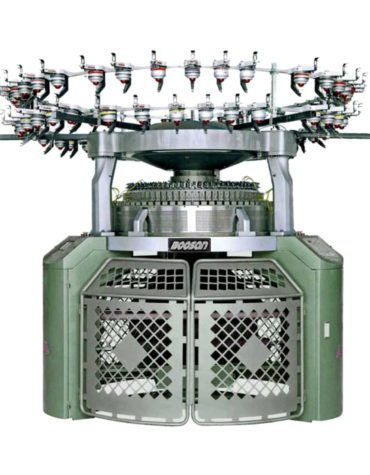

Double cylinder narrow weaving JYF5 8/55 fields have a wide variety today and are used in many textile sectors according to their intended use. While weight and tonnage are taken into consideration in the usage areas of these machines, the type of machine varies according to the material used and the type of yarn. Narrow weaving machines have more than one name according to their usage areas; air jet narrow weaving machine.

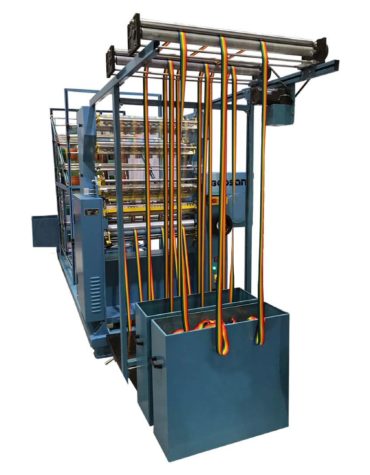

Features of Double Cylinder Narrow Weaving Machine

| Model (Single roll single weft) | 8/27 | 10/27 | 6/50 | 8/50 | 4/65 | 6/65 | 14/20 | 12/27 | 10/30 | 10/35 | 8/45 | 8/55 | 4/110 | |||

| Model (Double roll double weft) | 8/27 | 10/27 | 6/45 | 8/42 | ||||||||||||

| weaving head | 8 | 10 | 6 | 8 | 6 | 8 | 4 | 6 | 14 | 12 | 10 | 10 | 8 | 8 | 4 | |

| Weaving head width | 27 | 27 | 45 | 42 | 50 | 50 | 65 | 65 | 20 | 27 | 0 | 35 | 45 | 55 | 110 | |

| Number of frames | 20 | — | ||||||||||||||

| Roles | Single Roll | Single Roll | Single Roll / Double Roll | |||||||||||||

| jacquard hooks | — | Standard Configuration: Single crimp 16, double crimp 14” | ||||||||||||||

| Weft density | 3.5 – 36.7 cm (8.9’’ – 93’’ inch) | |||||||||||||||

| Engine | 2 HP | |||||||||||||||

| pattern chain loop | 1:8 1:48 | |||||||||||||||

Main Features

- Easy adjustment capability

- Changing bands as needed

- small volume

If you want to see more models of our machines click the link here