- You have no items in your shopping cart

- Continue Shopping

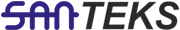

Mix embroidery machine combined flat embroidery, sequin embroidery, bead embroidery, cording embroidery, laser cutting in one machine. To realize one machine of multi function and multi use, which will bring you an amazing and colorful embroidery work, meanwhile, also improve your production efficiency greatly. On the high-end brand embroidery with excellent performance.

Product Features:

Integrates many embroidery methods such as flat embroidery, sequin, bead, cording, laser cutting, etc, thus making embroidery methods flexible and variable

The automatic-conversion flat embroidery head and lock stitch chenille head make flat embroidery and lock stitch chenille converted at random

The spacing between the lowest position to which the presser foot falls and the needle board can be rearranged as well as the working height of the presser foot while making embroidery drapery and the embroidered matter on computer

After lock stitch chenille embroidery head is finished the work, the presser foot can rise automatically and the material tray will automatically return to the original position to get into the wait state, thus facilitating frame and material changes

Many embroidery effects such as cording embroidery, taping embroidery, cording embroidery, frill embroidery and zig-zag sewing embroidery can be realized by choosing attachments and computer parameters

Optional Devices

Laser cutting device

Power: 220V

Laser Type: Sealed off CO2 laser

Laser Power: Rated power 75W, peak power 90W, momentary maximum peak can be 100W

Accuracy of Power Control: Rainbow computer control system, accuracy control mode, power can be subdivide to 0.1%

Cooling-down Method: Water coiling down

Supporting System: Air inlet and outlet system

Auto up-down System: Ensure the position of laser cutter head

Light Spot: TEM00, accuracy adjustable, the smallest can reach 0.01mm

Cutting Thickness: Have unique advanced level of CNC cutting technology, independent digital power is adjustable layer cutting, perfect technology supporting max 256 thickness of material cutting

| Model | Number of Needles | Number of Heads | Head Spacing | Working Width | Length |

|---|---|---|---|---|---|

| YX-GP602+02/600/100 | 7 | 2 + 2 | 350 + 250 | 600 x 1000 | 3530 x 2590 |

| YX-GP606+06/600/100 | 7 | 6 + 6 | 350 + 250 | 600 x 1000 | 5530 x 2590 |

| YX-GP912+12/500/1400 | 10 | 12 + 12 | 390 + 210 | 500 x 1000 | 7990 x 3390 |

| YX-GP618+18/600(1350)/1300 | 7 | 18 + 18 | 400 + 260 | 1350 x 1300 | 15930 x 3190 |

| YX-GP920+20/460(920)/1000 | 10 | 20 + 20 | 260 + 200 | 920 x 1000 | 12295 x 2680 |

| YX-GP423+12/330(1200)/1200 | 5 | 23 + 23 | 165 + 165 | 1200 x 1200 | 11325 x 3120 |