- You have no items in your shopping cart

- Continue Shopping

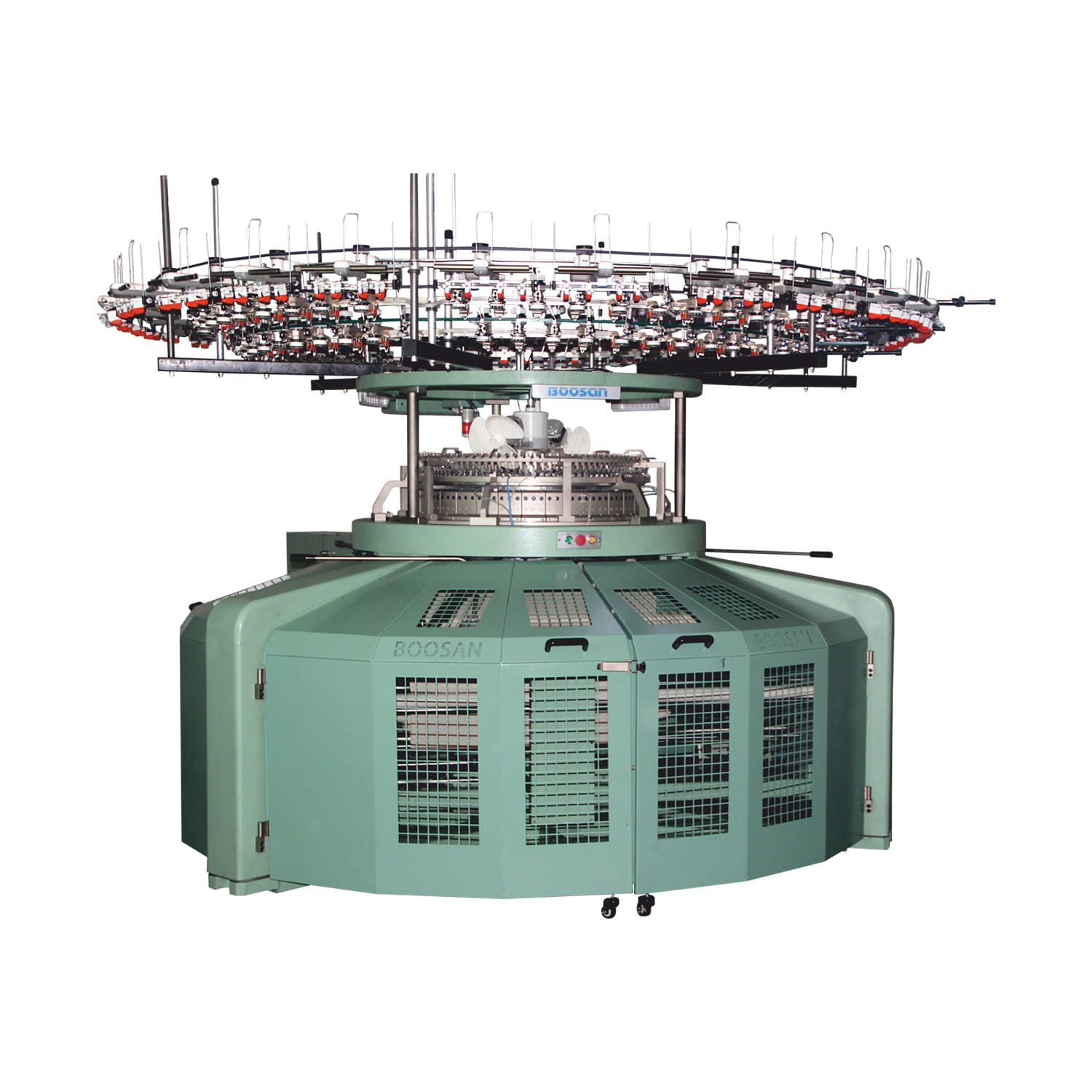

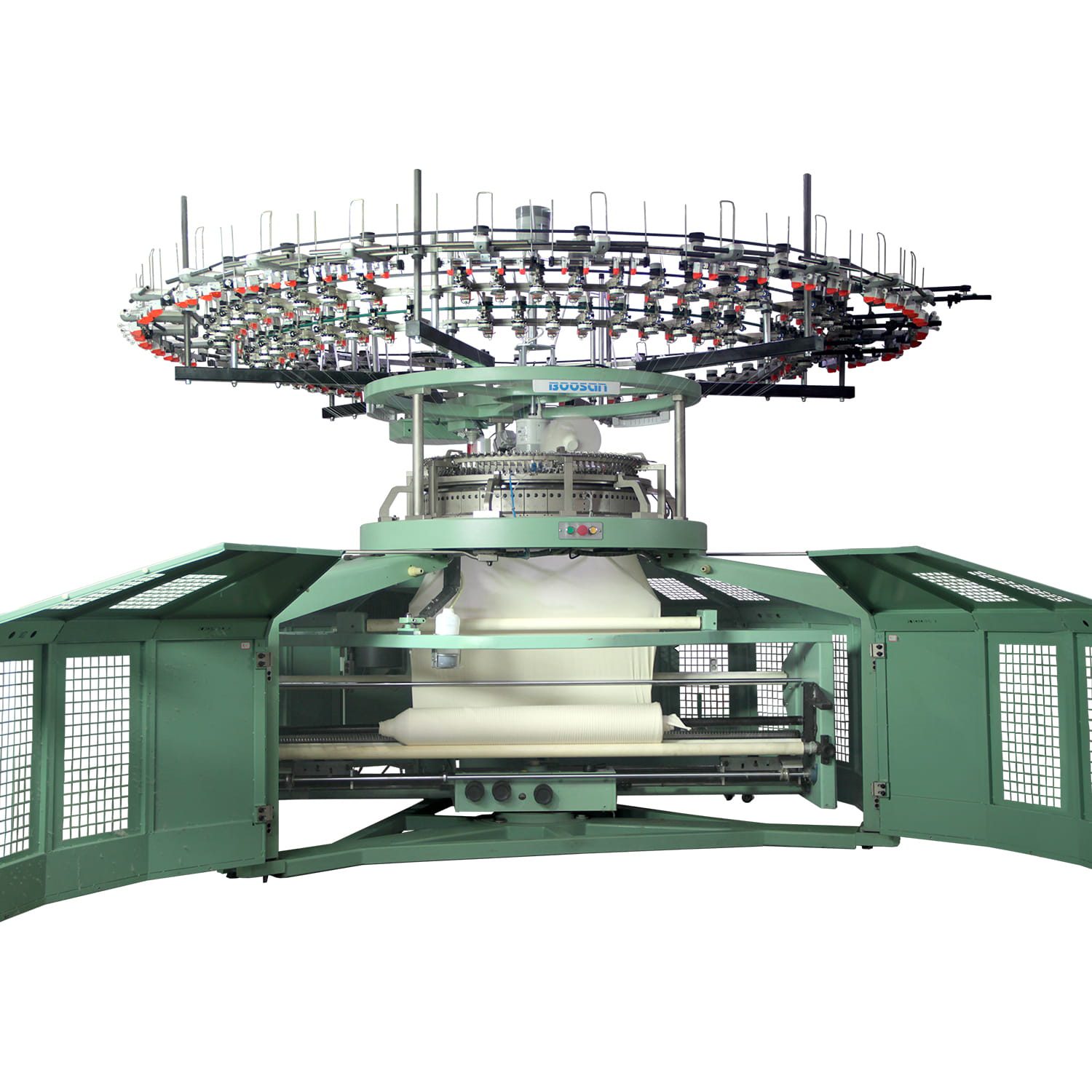

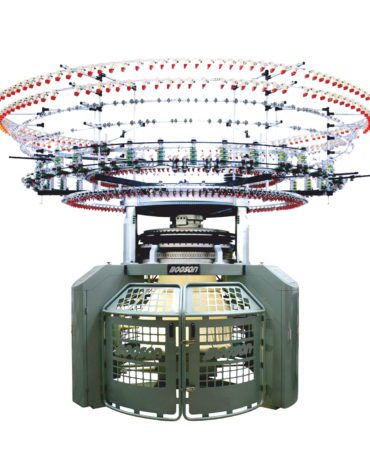

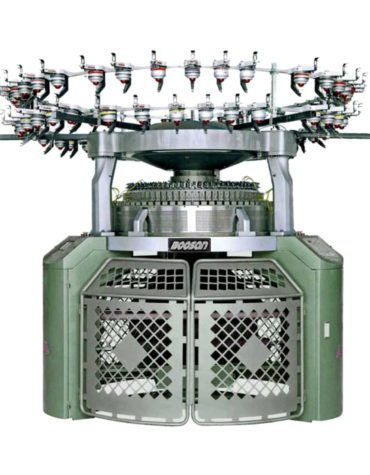

Single Jersey Fabric Knit Machine (Open Width – Four Tracks) PLT3

$1.00

Single Jersey Fabric Knit Machine (Open Width – Four Tracks) PLT3

Please contact us for more details information contact form.

Single Jersey Fabric Knit Machine (Open Width – Four Tracks) PLT3

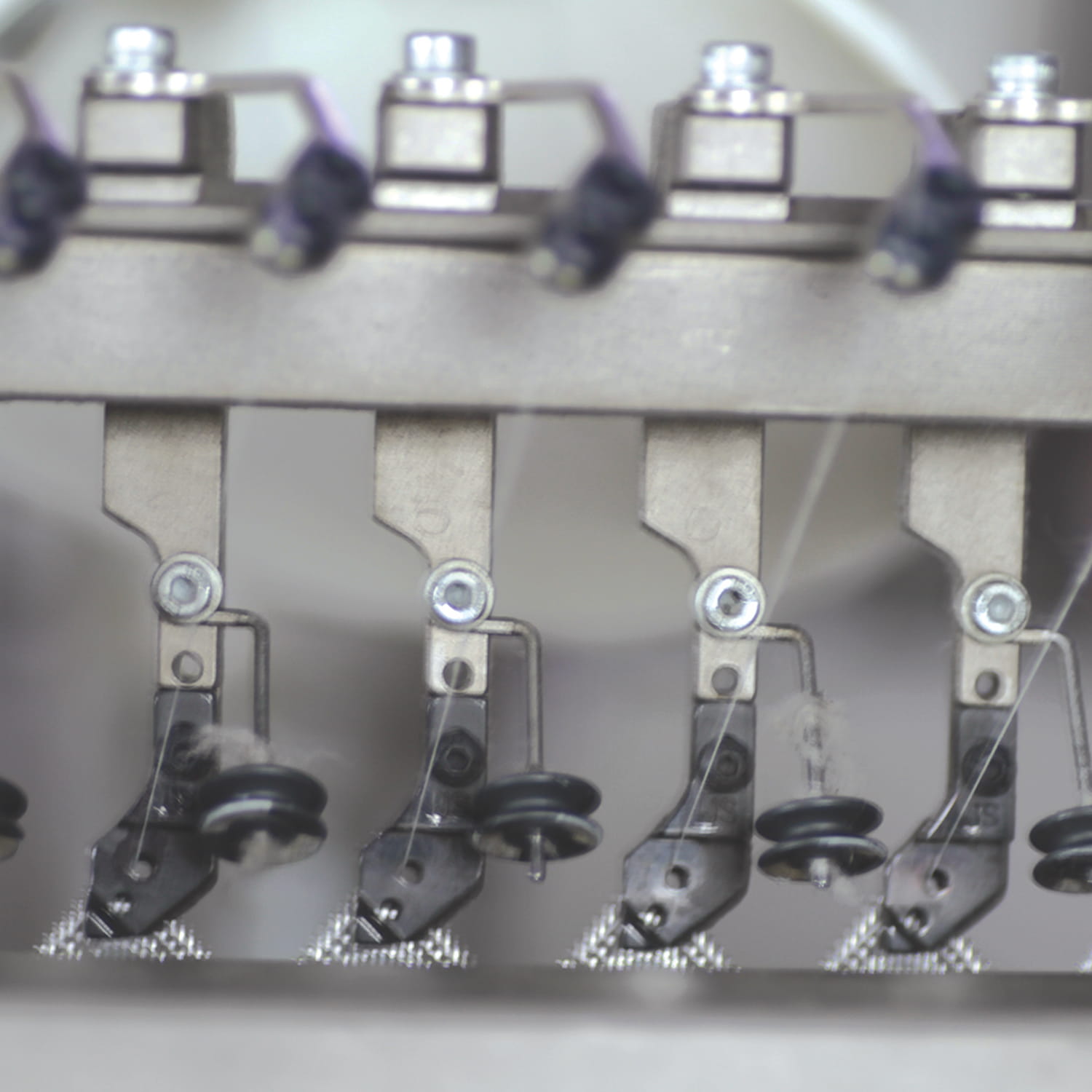

Textile Head

| Cylinder | Mounted on an oil immered bearing ring, to guarantee the necessary prescision in long time work. |

|---|---|

| Needles | Groz-Beckert |

| Sinkers | Kern Liebers |

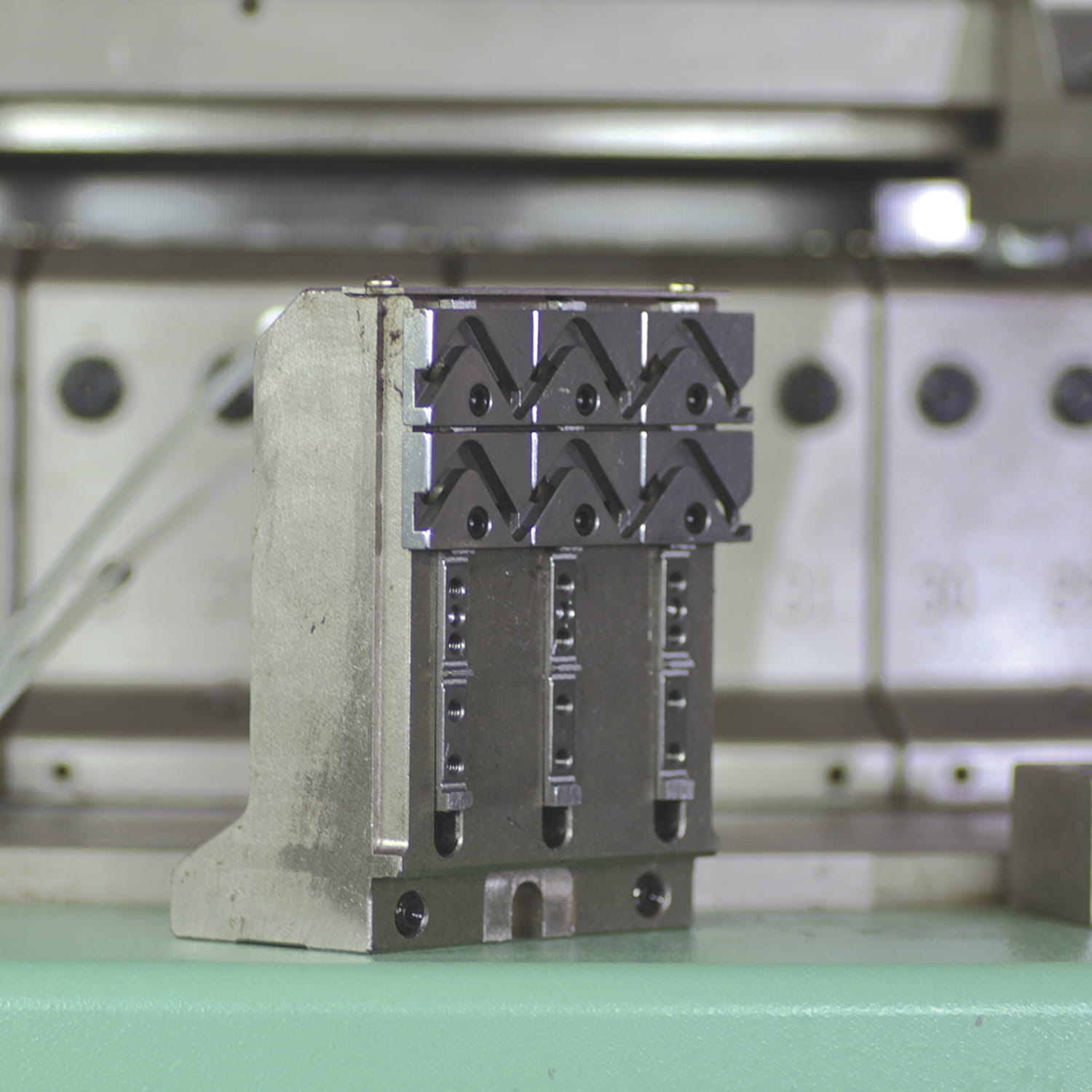

| Closed Track Cylinder Cams | ±0.5 mm standard excursion for high velocity (without unwanted spikes). The Ø 30″ inch machine can normally work with Lycra at 30 / 35 rpm. |

| Cam Boxes | Cast iron for better quality, dimensional stability, vibration abetment, guarantees efficiency over the years and it does not deform or squeeze in the solicited areas. |

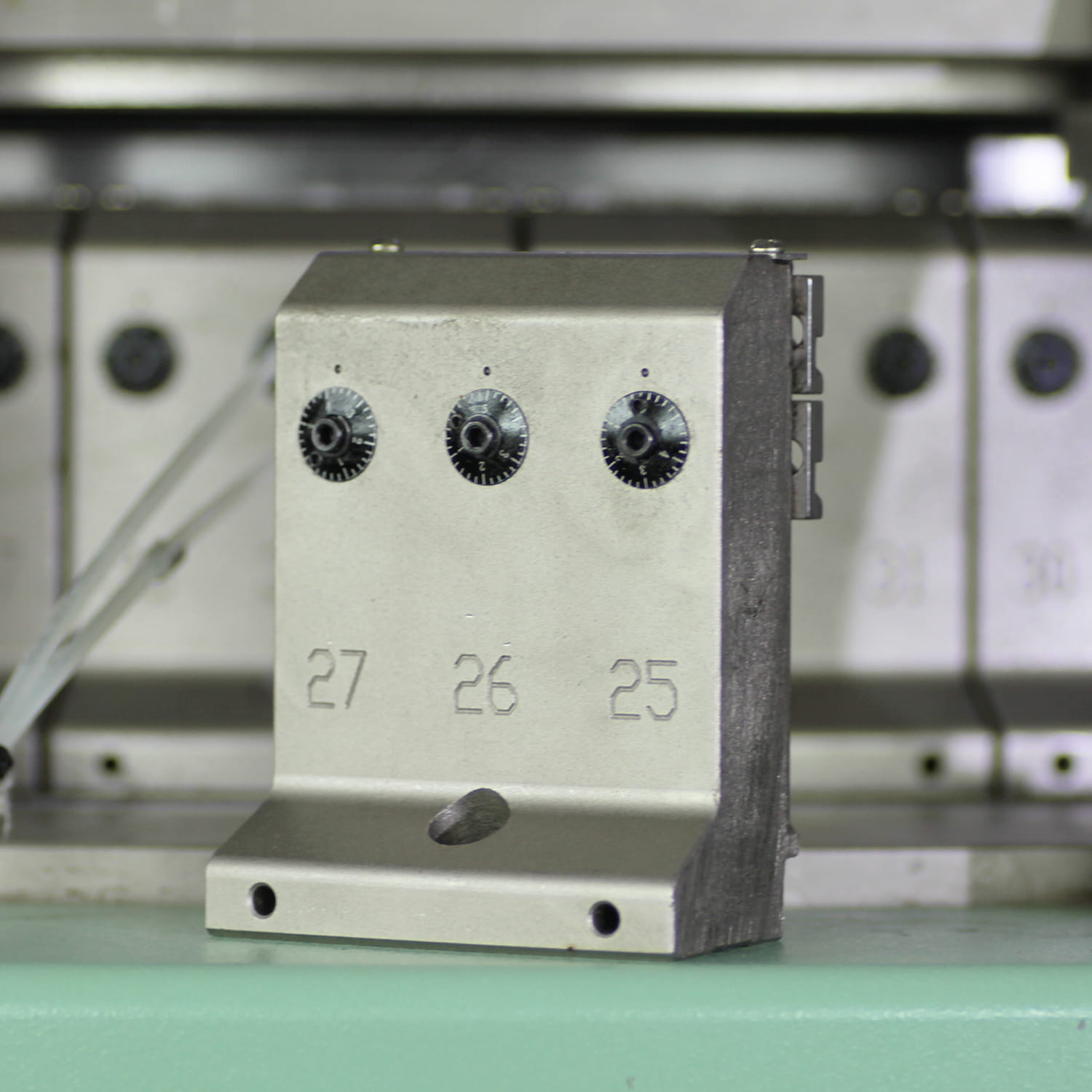

| Stitch Length | Adjustable on each feed with a high precision micrometric register. |

| Plate Carrying Sectors | Operator friendly centralized adjustment of the stitch length (without blocking screws of the system). High precision (1/100) comparator for the movement control. |

| Yarn Feeder | The machine is equipped with Zirconium feeders.The black color is ideal for optimal yarn visibility.

Zirconium guarantees a long lifetime before being damaged by yarn rubbing. The feeder is with three holes for a separate yarn control. Allows the production of an excellent quality plated jersey (Vanisê) Allows the production with there different yarn contemporary. Allows the production of there thread plated jersey (Trivanisê). |

| Sinkers Ring | The profile of the sinker’s cams is optimized to allow production of plated jersey with Lycra and high speed working angles.The sinker ring and the relative cams work suspended over the cylinder, which they never contact avoiding dangerous friction. |

| Cylinder | Built using the most advanced and precide technologies.The needle housing are formed by tempered steels sticks with high hardness, fluency and mounted with micrometric precision.

The sinkers housing are obtained with micrometric precision in tempered steel rings with high hardness and fluency to guarantee a long lifetime. |

Single Jersey Fabric Knit Machine

Ergonomics

The project of the machine has been realized keeping in the highest consideration the needs of the operator.

- Ease of accesss to the needles and yarn feeders.

- High visibility of the needle, sinker shape and the area of the knitting formation.

- Ease of access to all the adjustments.

- Limited feeder ring height from the ground.

- Step layout of the feeder rings.

- Continuous electronic speed adjustment.

Centralized stitch length adjusting system.

Positive storage feeder adjustment from the exterior.

All the non green painted parts of the machine are treated in a special way with “Opaque Chemical Nickel Plating” which guarantees no oxidation.

| Diameter | 26″ inch | 28″ inch | 30″ inch | 32″ inch | 34″ inch |

|---|---|---|---|---|---|

| Gauge | 14 ~ 40 | ||||

| Feeds | 78 | 84 | 90 | 96 | 102 |

| Speed (rpm) | 35 | 35 | 35 | 28 | 28 |

Single Jersey Fabric Knit Machine

Standard Equipment

- Navigator Memminger Iro control device

- Electronic speed control device

- Positive storage feeders

- Yarn creel with aluminium tubes

- Automatic lubrication

- Centralized stitch length adjusting system

- One shift rev. counter

- Self cleaning system

- Automatic cleaning device at the end of each roll

- Air distributor

- Scanner

- Three thread plated yarn guides (Trivanisê)

- Two closed cam tracks, suitable for the production of Jersey Fleece ad pique.

Optionals

- High legs frame (Roll diam, up to 75 cm)

- Footboard for high legs frame.

- Lycra feeding system.

- Cam for four tracks.

- Self threading yarn creel.

Single Jersey Fabric Knit Machine

Electrical Specification

Electric equipment with Navigator Memminger Iro device for complete management for all the functions, with possibility to export and store production date.

| Inverter | Excellent quality, well dimensioned: 5.5 kW (7.5 HP) |

|---|---|

| Main Electrical Motor | Well dimensioned 5.5 kW (7.5 HP) |

| Electric Cabinet | Excellent vention for optimal temperature control. |

| Electric Cables | Separetely wired from the machine for easy maintenance. |

| Safety | In case of danger, the Emergency button shuts down the machine and the electrical system (CE compliant). |

| Signaling Lights | Colored lights indicate different stopping cause. |

| Morning Timer | Prevents the machine start up at maximum speed before a warm up cycle (according to the operator settings). |

| LFA Monitor | Electronicy yarn consumption measuring device, up to 5 tracks (LFA: Lenght of Absorbed Yarn for each cycle of the machine). |

| Scanner | Identifies various types of defects in the fabric, and allows for automatic mahine stop. |

| Data Collection | Posibility to connect a PC in an easy way. |

Cleaning

| Automatic Cleaning | Allows manual operation of the machine for inspection. |

|---|---|

| Cleaning Cycle | At the and of the roll (automatic and adjustable) keeps the textile head, needles and sinkers perfectly cleaned. |

| Fans | Powerful fans on the cylinder and feeding rings (the assure an optimal cleaning of yarn and feeders during production). They can be used also during machine down time to avoid lint accumulation. |

| Fans Rotation | Engine controlled, guarantees constant speed. |

| Timed Air Blast | Allows perfect cleaning of the yarn guides avoiding obstruction with cotton dust/lint. |

Frame

| Manual Control | Allows manual operation of the machine for inspection. |

|---|---|

| Protection Gates | CE compliant for maximum operator security (the machine can not be operated with out complte closure of all gates). |

| Safety | Device for automatic machine shuts down in case the fabric falls underneath the take-down. |

| Working Group of the Positive Storage Feeders | Takes motion directly from the cylinder ring without unwanted movements.Adjustable from the exterior, for ease of use.

Interchangeable noiseless synthetic gears. Safety device for the production carter closing. |

| Lighting | Textile head illuminated by high efficiency, and low consuption fluorescent lights. |

Lubrication

| Pulsonic 5.2 Pump | Memminger Iro oil system lubrication without fog formation. Very low air consumption for lubrication. |

|---|

Open Fabric Take-down Features

| Maximum Fabric Width | 2.300 mm |

|---|---|

| Maximum Fabric Roll Diameter | Ø 412 mm |

The fabric take-down works with only mechanical movements. There are no electrical or electronic parts that can be damaged by dirt or humidity.

It has motorized rubber bars (Black) that allow to achieve a low fabric tention.

The fabric obtained with this take-down has double the height compared to the one, obtained with the same tubolar machine, with the same characteristics of weight, both in the middle and on the sides of the fabric roll.

The unroll of the side of the fabric is guaranteed by tuneable, (both in the power and direction), air streams.

The opening of the fabric is guaranteed by high efficiency ceramic blade, that does not loose its sharpness in time.

Possibility to use the machine in tubolar mode with a simple and quick action on the take-down.

| Machine Weight (26″ inch – 34″ inch) | 2950 kg |

|---|---|

| Electrical Power Installed | 6,5 kW |

| Compressed Air Consumption | 280 lt/min |

| Working Pressure (Air) | 6 Bar |

| Acoustic Pressure | 82,3 dB(A) |

After the weaving most common method of manufacture textile products is knitting. To understand the Circular knitting machine we have to understand what is the knitting?

There is two main way to textile techniques to knit. Weft and Warp Knitting. The difference in weft and warp knitting originates in the way the needles move during the production and in the way the yarn is supplied. Weft knitting is a one fibre technique, which means that only one fibre is needed to build the stitches. The needles are moved separately.

However, in the warp knitting technique needles are moved simultaneously. Therefore, all needles need the fibre material at the same time. Most important knitwear fabrics are circular knitted, warp knitted, flat-knitted fabrics and fully-fashioned fabrics.

Circular knitting machines always produce a tube-shaped fabric. They exist in different sizes or diameters, depending on the field of application. The needles and sinkers in these machines are arranged in a circle. The machines can be divided into two different types, depending on the number of sets of needles one of them is single set; plain and the other one is two sets: rib, interlock, spacer fabric.

Common products that are produced with circular knitted fabric are T-shirts. For production, nearly every material can be used. The form varies from filament to staple fibre yarn. For special purposes, also monofilaments and wires are used. Machines that possess just one set of needles are only able to produce plain- knitted structures.

For the production of this kind of fabric, two needle sets are necessary and the needles need to be arranged in a different way. The loops are formed in two different directions. The result is a fabric with smooth surfaces on both sides. This is due to the right loop structure on each side. The rib structure shows rib loops on both sides of the fabric. These fabrics can be produced using loop- or needle transfer.

Until now, circular knitting machines have been designed and manufactured for mass production of knitted fabrics. The special properties of knitted fabrics, especially fine fabrics made by the circular knitting process, makes these types of fabric suitable for application in clothing, industrial textiles, medical and orthopaedic garments, automotive textiles, hosiery, agro and geo textiles, etc. The most important areas for discussion in circular knitting technology are increasing production efficiency and improving fabric quality as well as new trends in quality clothing, medical applications, electronic garments, fine fabrics, etc. Famous manufacturing companies have pursued developments in circular knitting machines in order to extend into new markets. Textile specialists in the knitting industry should be aware that tubular and seamless fabrics are highly suitable for various applications not only in textiles but also in medical, electronic, agriculture, civil and other fields.

Principles and classification of circular knitting machines

There are many types of circular knitting machine that produce long lengths of tubular fabric manufactured for specific end uses. Single jersey machines are equipped with a single ‘cylinder’ of needles that produces plain fabrics, about 30 inches in diameter. Wool production on single jersey machines tends to be limited to 20 gauge or coarser, as these gauges can use two-fold wool yarns.

Another inherent feature of woollen single jersey fabrics is that the fabric edges tend to curl inwards. This is not a problem whilst the fabric is in tubular form but once cut open can create difficulties if the fabric is not finished correctly. Terry loop machines are the basis for fleece fabrics that are produced by knitting two yarns into the same stitch, one ground yarn and one loop yarn. These protruding loops are then brushed or raised during finishing, creating a fleece fabric. Sliver knitting machines are single jersey machines that have been adapted to trap a sliver of staple fibre into the knit structure.

Double jersey machines are single jersey machines with a ‘dial’ that houses an extra set of needles positioned horizontally adjacent to the vertical cylinder needles. This extra set of needles allows the production of fabrics that are twice as thick as single jersey fabrics.

| Weight | 2950 kg |

|---|